Neodymium Finished Catalysts to manufacture Synthetic Polybutadiene

Background

Current Neodymium catalyst systems utilized in the Synthetic Rubber Industry for the solution polymerisation of Butadiene, generate a small but significant portion of high molecular weight polymers, which yields “hard” rubber, that is difficult to process in the tyre industry. High molecular weight polymers also lead to polymer reactor fouling and gel formation in the rubber.

In addition, the rheological properties of rubber is influenced greatly by the presence of this small portion of high Molecular Weight (MW) rubber, by increasing the Mooney viscosity of the rubber. To compensate for this effect, bulk rubber average molecular weights have to be reduced, such that commercial specifications of Mooney 45 or 60 can be achieved.

This has a negative effect on physical properties of the rubber.

Any Neodymium Finished Catalyst system, consists of at least four distinct active catalyst complexes, each generating polymers at different reaction rates. The research of Comar Chemicals has concentrated on changing the distribution of the active centers present in a Neodymium Finished Catalysts, in order to generate catalysts that:

- Produce rubbers with narrow MW distributions, measured by the Polydispersity Index (PDI)

- Produce rubbers with the highest numbers based average molecular weight (Mn) for a given Mooney 45 or 60 rubber, thereby improving the physical properties of those rubbers

- Have a high catalyst monomer conversion activity

- Minimize the fraction of high MW polymers present in a rubber

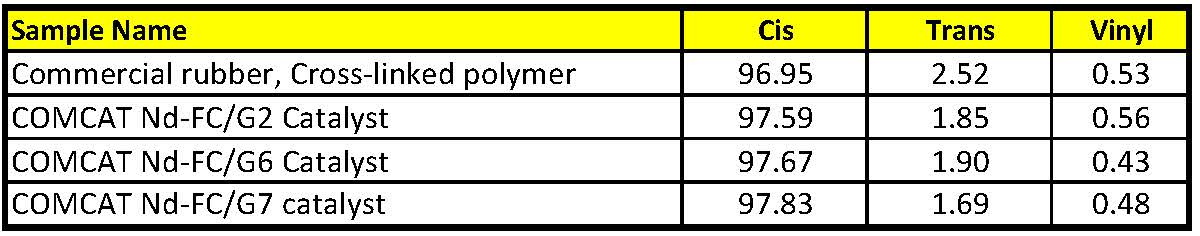

- Produce polymer with high CIS microstructure

Comar Chemicals (Pty) Ltd. is offering a number of pre-formed catalyst systems, that are compared in the technical discussion below.

Technical Discussion

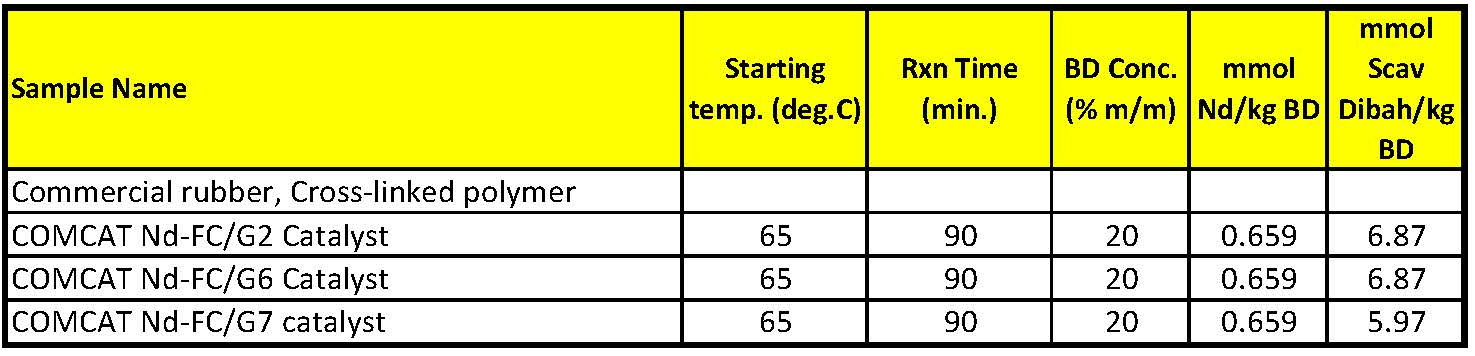

Standard polymerization tests have been done to compare the different COMCAT Nd-FC catalyst systems that are currently commercially available from Comar Chemicals, in comparison to a cross-linked commercial rubber.

Batch laboratory polymerization tests were performed adiabatically with the following conditions:

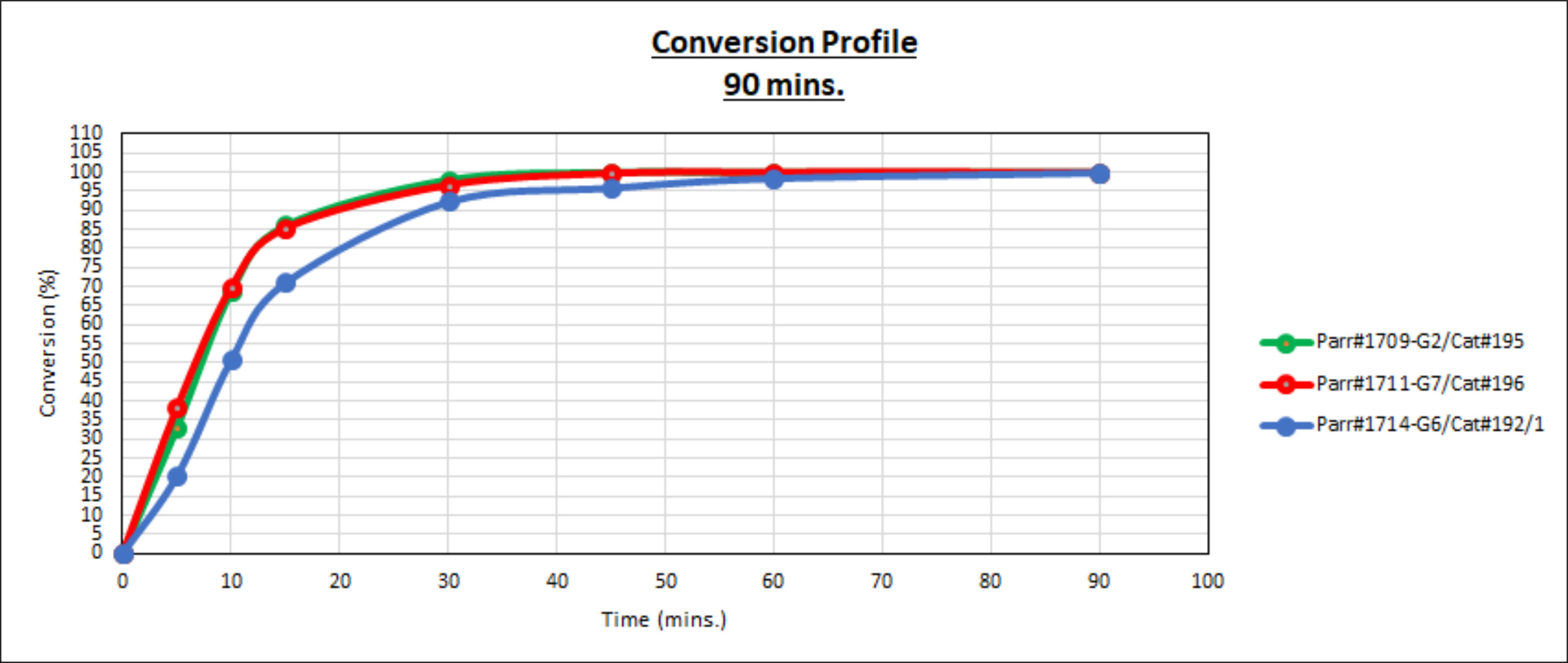

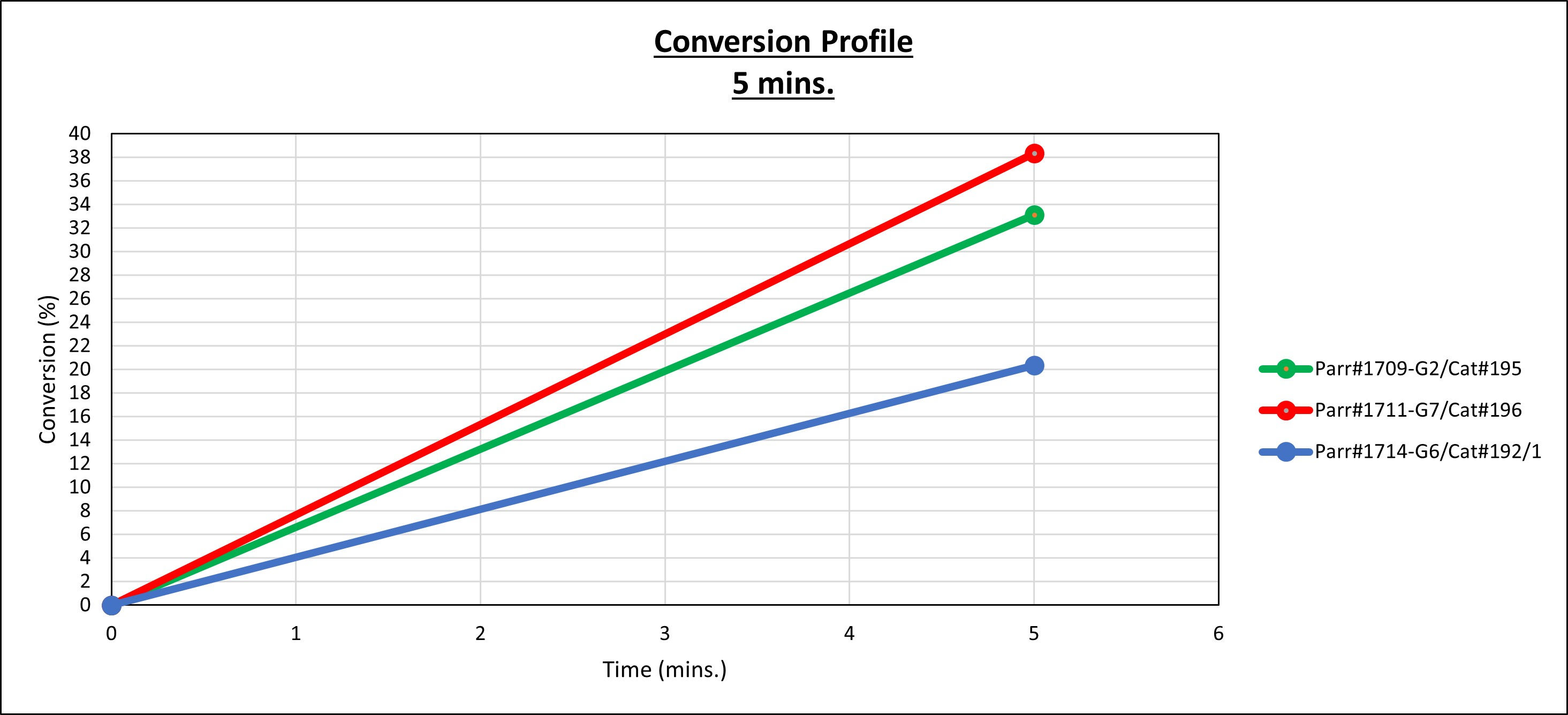

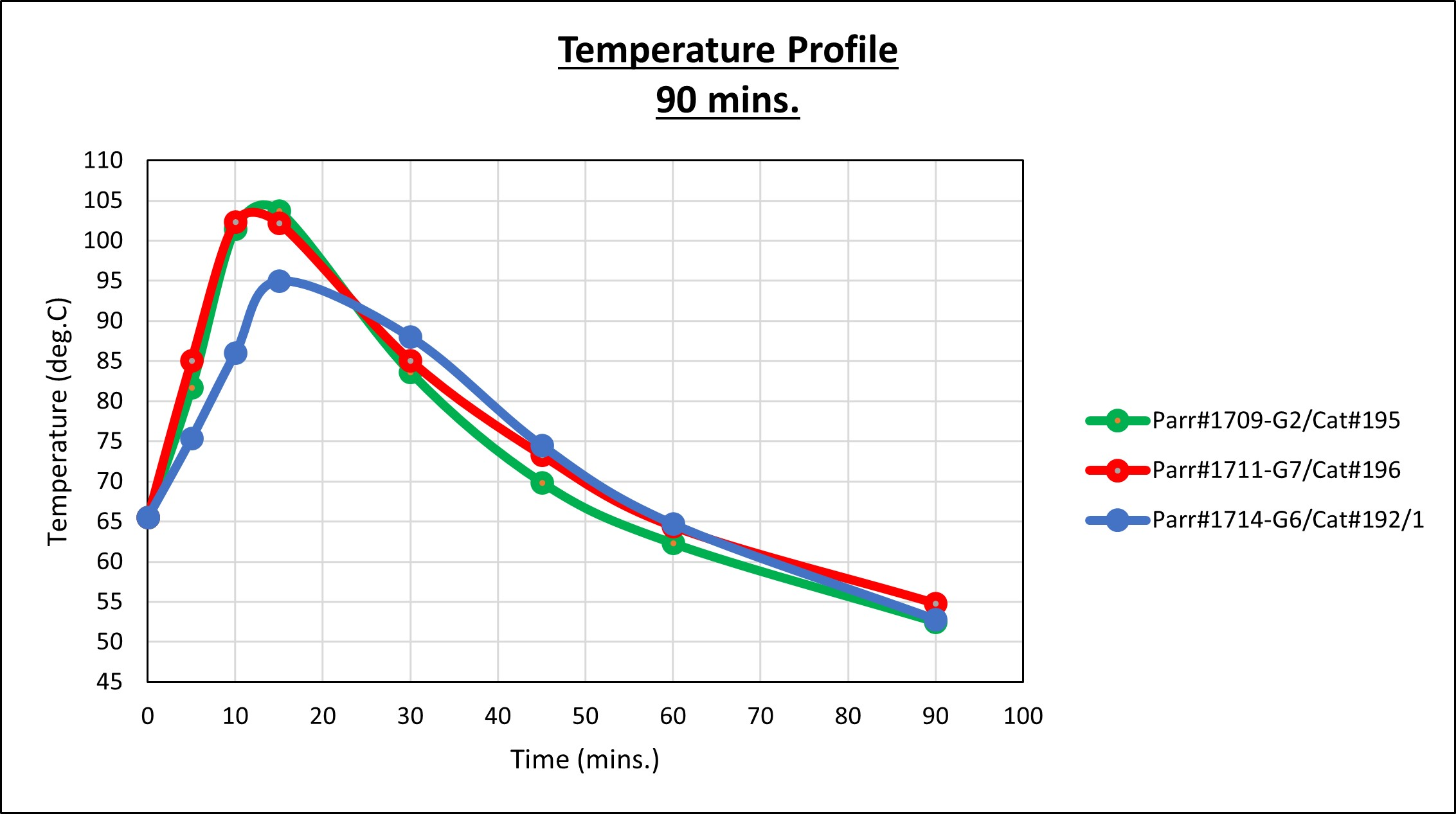

Catalyst Reaction Rates :

Temperature Profiles :

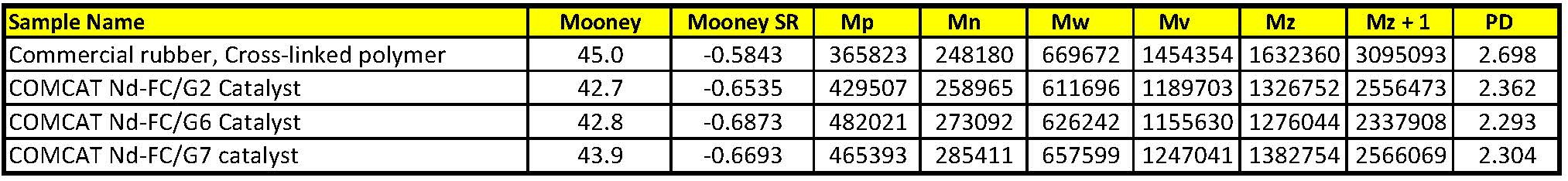

Rubber Characterisation by Mooney, GPC and Microstructure:

Analysis of the resulting rubbers in terms of Mooney viscosity, and Gel Permeation Chromatography (GPC) yielded:

Rubber Microstructure was measured by NMR as:

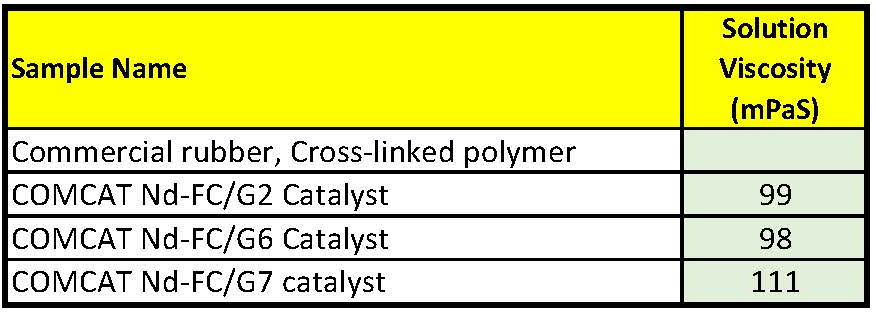

Hexane Solution viscosity

Polymers were dissolved in hexane to form 8 %m/m solutions of the polymers, which were tested for solution viscosity, which was determined at 25°C.

From this test, there is an indication from the rheological properties, that the Nd-FC/G7 catalyst produces rubber that behaves similarly to commercial cross-linked rubber.

It was also observed that in the case of reactions catalysed with Nd-FC/G7, once monomer had fully converted to polymer, Mn increased by about 10 % without there being free monomer present. Mn stabilized at final measured values, irrespective of reaction time.

It is postulated that the Nd-FC/G7 catalyst quality allows the manufacture of cross-linked polymers with a single catalysts system, without any negative effects on the resultant polymerisation system, such as fouling and gel formation.

Average Molecular weight: Mn

For the same Mooney viscosity, the Nd-BR with made with the Nd-FC/G7 catalyst has about 20 % higher Mn compared to a commercial grade rubber. It is also evident, that the development of the catalyst system from the G2 generation to the G7 generation, yielded increasing Mn for the same Mooney.

The COMCAT Nd-FC rubbers have a much narrower polymer MWD, and much less high MW “dangling” ends in the distribution, which has the following advantages:

- The polymers made with the COMCAT Nd-FC catalyst systems, are easier to process by tyre manufacturers.

- High MW polymers are insoluble, and cause polymer reactor fouling. The utilization of the COMCAT Nd-FC catalysts will therefore improve reactor fouling. This is further illustrated by the high Mz value of the commercial rubber, when compared to the rubbers made with COMCAT Nd-FC.

- Agglomerations of High MW polymers also cause “gel” formation in rubber, which is highly undesirable in processing of the rubber in tyre manufacture.

APPLICATION OF COMCAT Nd-FC TO MANUFACTURE SYNTHETIC POLYBUTADIENE AND POLY-ISOPRENE

It is possible to use COMCAT Nd-FC as ready-made catalysts on their own to polymerize 1.3-butadiene, to manufacture a polymer that is easy to process by rubber compounding systems, yet provide very good physical properties of vulcanized rubber.

Whilst the common application of COMCAT Nd-FC is in Polybutadiene synthesis, it is equally possible to use COMCAT Nd-FC for the synthesis of Poly-Isoprene.

Well documented Industry practice is to use a co-catalyst, such as Di Butyl Aluminium Hydride (DiBAH), in addition to a finished catalyst in all polymerisation reaction systems. The purpose of the additional DiBAH dosage into the solvent/monomer mixture, is as follows:

1. Scavenging Agent: DiBAH will remove residual water and other impurities in the solvent/monomer stream, thereby preventing catalyst degradation due to these impurities.

2. Chain Transfer Agent: DiBAH acts as a chain transfer agent, thereby allowing simple control of average polymer molecular weight, and Mooney viscosity of the rubber.

Catalyst systems employing the use of DiBAH, tend to be more cost effective, but some compromise between rubber quality and catalyst system cost is normally accepted.

Control of a Polymerisation reactor is a multi-variable problem. Many factors play a role, such as:

- Feed Butadiene concentration

- Nominal Average Reactor Residence Time

- Non-ideal Reactor Residence time distribution due to factors such as back mixing, stagnant zones, build-up of fouling

- The Number of CSTR’s in series yielding performance varying from mixed to semi-plug flow

- Adiabatic or Isothermal reactor temperature control

- Feed and final polymer temperatures

- Impurities in feed streams

- Catalyst quality (distribution of active catalytic centers)

- Catalyst to Monomer dosage ratios

- Co-catalyst dosage, if any

All of these factors will combine in rubber synthesis to affect the product quality of polymers.

TECHNICAL SUPPORT

Comar Chemicals will provide 1 l samples of COMCAT Nd-FC catalysts, on customers request.

The information regarding the necessary laboratory procedures and practices to test COMCAT Nd-FC catalysts safely and with the best results, is provided via this link.

Comar Chemicals (Pty) Ltd is furthermore able to assist customers in the decision which of the available COMCAT Nd-FC catalysts are appropriate for a customers’ polymerisation plant. In addition, detailed polymerisation recipes will be provided, to optimise catalyst system costs, whilst achieving the desired rubber compound physical properties.

Comar Chemicals (Pty) Ltd. is able to deploy a team of technical experts, to assist customers on site with plant trials of the COMCAT Nd-FC catalyst systems.

COMMERCIAL USE OF COMCAT Nd-FC CATALYSTS

Both the COMCAT Nd-FC/G2, and the COMCAT Nd-FC/G6 catalysts are used commercially in bulk by a number of synthetic rubber producers, in South East Asia, Europe and the USA.

Comar Chemie AG in Switzerland produces Catalysts COMCAT Nd-FC/G2 and COMCAT Nd-FC/G6 in bulk tonnages, in a highly automated Preform catalyst plant, and these catalysts can be supplied worldwide in special designed refrigerated Isotank containers.

COMCAT Nd-FC/G7 is the latest development in the catalyst series, that is in the process of being commercialized, and as such represents the state of the art of Comar’s catalyst know-how.

APPLICATION OF COMCAT Nd-FC TECHNOLOGY

COMCAT Nd-FC finished catalysts are particularly suitable for the production of synthetic Polybutadiene rubber for use in the tire industry for the manufacture of high performance radial tires for passenger vehicles, that need to meet the stringent requirements of new legislation aimed at reducing the environmental impact of automotive mobility.

The Polybutadiene rubber made with COMCAT Nd-FC/G7 yields the highest average molecular weight rubber for a given Mooney viscosity, and thus this rubber can be used to manufacture tires that exhibit low wear of tire treads, which is particularly important for tires suitable for Electric Vehicles, where standard rubbers yield tires that wear faster, due to the heavy load imposed on these tires by the weight of the battery systems.

POLYMER PLANTS

COMCAT Nd-FC catalysts can be used in Solution polymerisation plants, that are operated in continuous or batch mode.

It is possible to convert existing Polymer Synthesis plants with the minimum capital investment to the use of the COMCAT Nd-FC catalyst systems.

COMCAT Nd-FC catalyst can be applied in a variety of solvent systems.